So, you have become enamored with timber frame home designs, but you’ve encountered some terms you are unfamiliar with. Exactly what parts make up a timber frame? And how do those timber frame parts go together?

In this post, we have compiled a list of terms and definitions. Whether you are a longtime timber frame enthusiast, or if you are new to this centuries-old craft, using these terms allows everyone to be on the same page when designing and building your dream home.

The Ancient Art of Timber Framing

In contrast to conventional 2×4 “distributed load” construction, timber frame structures are “point load” construction, where a few brawny vertical and horizontal beams shoulder the weight of the home. In fact, many timber frame structures contain fewer than 200 key structural components. This structural strength advantage means one does not need load-bearing walls within the interior of the structure, so one can design the layout in any configuration you desire.

- Post & Beam: This is the first term that should be addressed because for years it was interchangeable with “timber framing.” In fact, when Woodhouse was first founded it was named Woodhouse Post & Beam. Now, post and beam refers to a construction system very similar to timber framing, except it uses metal fasteners to create the frame instead of traditional joinery. These fasteners include plates, screws, and through-bolts. As timbers shrink and swell with the seasons, metal fasteners may loosen over time, and may need to be re-tightened.

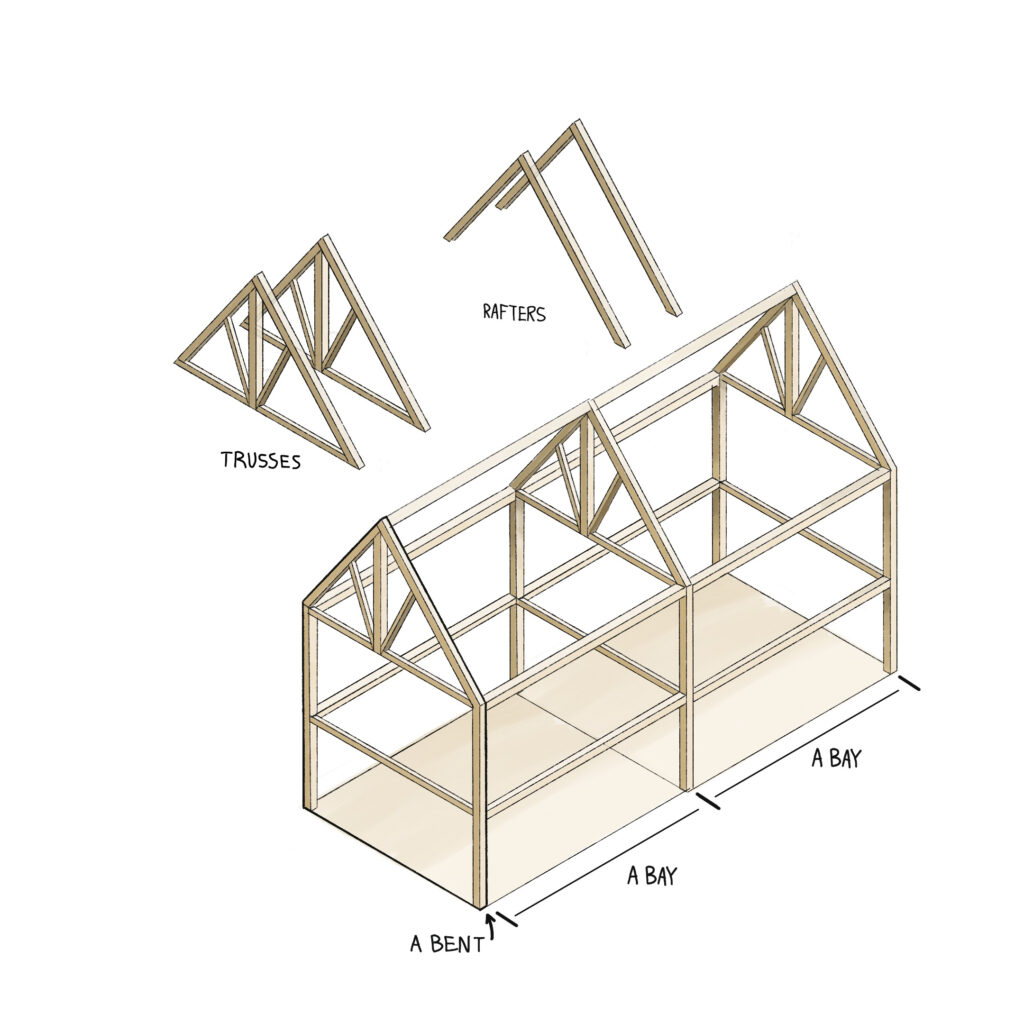

- Bent: The walls of a timber frame structure are made of horizontal beams that are parallel to the ridge beam at the top of the structure. The opposing walls take shape with vertical posts, horizontal beams, and a truss (a triangle of timbers) to form cross-sections, called Bents. Bents are the main load-bearing assembly in a timber frame.

- Bay: A box-like structure that consists of at least two bents, at each end of the bay, with frame members that connect the bents to create a load-bearing frame.

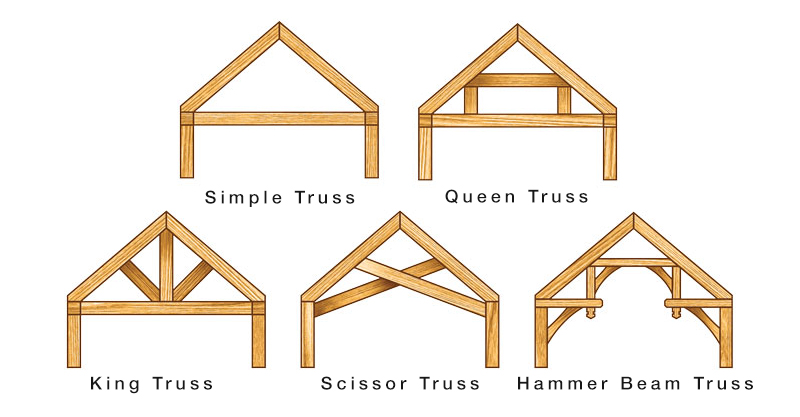

- Trusses: In timber framing, trusses are the focal point of the home’s design, drawing our attention upward. This feature is why timber framing remains so popular for places of worship. The truss carries the weight of a second floor or roof system to the walls without any support from below

- Common Truss: This is a simple triangle, used to support a roof in smaller buildings. A truss combines horizontal and vertical timbers to span a greater interior space, while carrying the structural load. Trusses are crafted during the construction of a bent.

- King Post: Adding a king post in the center of a truss triangle allows for a wider span. It consists of a central vertical post extending from the bent plate or girt to the junction of the rafters, usually with two supporting struts on either side.

- Queen Post: This truss looks like a rectangle within a triangle. It involves a pair of vertical posts of a roof truss standing on the bent plate or girt, and supporting the rafters or collar tie.

- Hammer Beam: These are the most dramatic in appearance, they have an open-air center, thanks to not having a chord (the bottom tie-beam found in other truss styles,) creating a large span with relatively short timbers. This can be an advantage if you are building with a species in which long, straight timbers are not plentiful.

- Scissor Truss: These trusses differ dramatically. They are made with double bottom chords that meet in the center of the truss and “scissor” together before continuing onto the top chord, sometimes they are reinforced by crossing with a vertical king post. Scissor trusses are an engineering marvel that provides vertical height to interior spaces. These trusses are used in homes with steep roof pitches, typically an 8/12 roof pitch or greater. (Roof pitch is defined by the number of inches of rise per foot of run. Thus, a 45-degree roof has twelve inches of rise for each foot of run and is called a 12/12 roof pitch.)

- Common Truss: This is a simple triangle, used to support a roof in smaller buildings. A truss combines horizontal and vertical timbers to span a greater interior space, while carrying the structural load. Trusses are crafted during the construction of a bent.

Learn more from Timber Home Living: The Ultimate Guide to the Different Types of Trusses for Timber Frame Homes

- Embellishment: A decorative feature added to a timber frame truss to add visual interest.

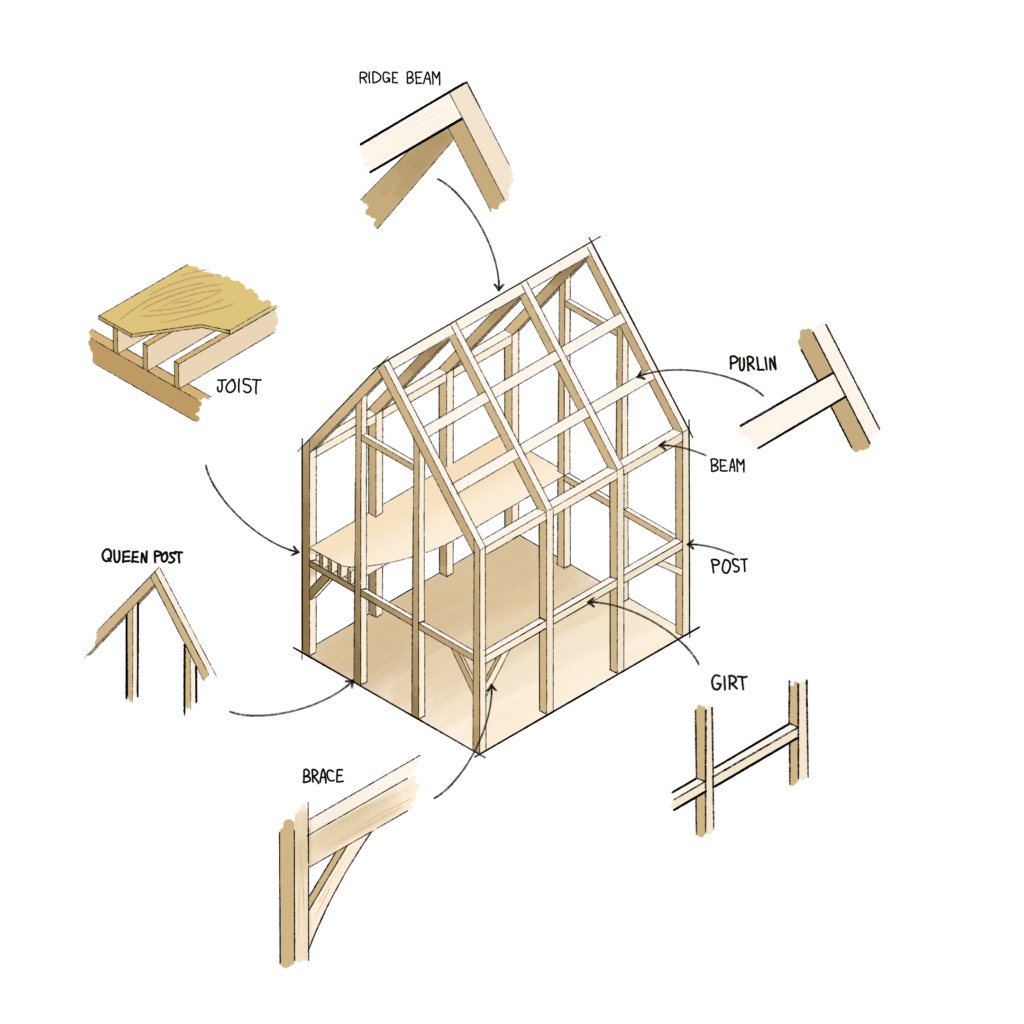

- Sills: large beams installed on top of the foundation walls, secured with anchor bolts.

- Girt: A key horizontal timber or beam used to connect posts or sills. A girt running in the wall direction is called a wall girt and a girt running in the bent direction is called a bent girt. This is where the modern term “girder” comes from.

- Vertical Posts: The legs of a timber frame. Each has its own name and function:

- Principal post – used at the corners of a structure.

- King Post: A vertical post that runs from a girt or ties to the ridge. The rafters join with the post to form a king post truss.

- Samson post – supports the intersection of four horizontal upper story beams.

- Joweled post – fashioned from a whole tree turned upside down to utilize the natural flare of the trunk. Also called a gunstock post.

- Plate: the perimeter of floor sections upon which posts stand

- Joist: Used to support floors

- Purlin: used between exterior posts to tie roof sections together

- Ridgepole: the horizontal apex of the roof system. Also known as a ridge beam.

- Horizontal Beams: These include timber sills or plates, girts, joists, purlins, and the ridgepole

- Roof frame: These are composed of rafters, struts, purlins, and ridge beam(s). The design and engineering strategy will calculate shape, roof pitch, loading, tree species, timber lengths, home’s design, and a myriad of other factors.

- Rafters: These are roof support timbers that extend from the top wall plate to the topmost ridge beam or opposing rafter.

- Braces: Braces come in different designs, shapes, and sizes, but their primary function is to provide rigidity to the frame by being installed diagonally wherever posts and beams are fastened together, both on vertical and horizontal planes. Braces are key for the frame to withstand high winds and snow loads.

- Structural Insulated Panels: Commonly referred to as SIPs. SIPs are an option for insulating your timber frame and enclosing the structure in a tight thermal envelope. They are made by sandwiching a layer of foam to two layers of OSB forming a structural panel.

- Cantilever Beam: A timber that projects out from a wall or post and supports an overhang.

Joinery Terms

- Mortise and Tenon Joint: A fastening method in which a projection on one end of a timber is inserted into a mortise (groove or slot in another timber), then fastened with a wooden peg or tenon. Subcategories include:

- Open mortise – a mortise that has only three sides.

- Stub mortise – a shallow mortise, depth depends on the size of the timber; also a mortise that does not go through the timber (as opposed to a “through mortise”).

- Through mortise – a mortise which passes entirely through a timber.

- Wedged half-dovetail – a mortise where the back is wider, or taller, than the front, or opening. The space for the wedge initially allows room for the tenon to be inserted, the presence of the wedge, after the tenon has been engaged, prevents its withdrawal.

- Through wedged half-dovetail – a wedged half-dovetail mortise that passes entirely through the piece.

- Housed joinery – a pocket is created in one timber to contain the entire end of another timber or frame member. Housing helps resist the twisting and checking of the housed member and hide gaps that can appear as the timbers shrink.

- Bird’s Mouth: A V-shaped notch that resembles a bird’s open beak. It is cut into the base of a rafter and received by the plate.

- Bridging: Short pieces of wood placed between beams or joists to prevent lateral movement.

- Dovetail: A tenon that is shaped like a dove’s spread tail to fit into a similarly shaped pocket cut, one of the strongest joints in timber framing to prevent interlocked timbers from moving.

- Pocket Cut: Similar to a mortise, but it is cut to receive similarly shaped tenon or tusk at the end of a connecting timber.

- Shoulder of Timber: Point of intersection at the joint of two assembled timbers with tenon(s).

- Spline: An engineered wood element placed in slot cuts to strengthen joints between two beams that meet at the same post, on the same plane. Spline and beams are secured with multiple tenons.

- Step-Lapped Rafter Seat: A modified birdsmouth, where rafters meet top plates, to resist downward, outward, and side-to-side thrust.

- Tenon: The projecting end of a timber that is inserted into a mortise.

- Stub tenon – a tenon that is shorter than the width of the mortised piece so the tenon does not show.

- Tusk tenon – a kind of mortise and tenon joint that uses a wedge-shaped key to hold the joint together

- Through tenon – a tenon which passes entirely through the piece of wood it is inserted into, being clearly visible on both sides.

- Teasel tenon – a term used for the tenon on top of a joweled or gunstock post, which is typically received by the mortise in the underside of a tie beam; a common element of the English tying joint.

- Top tenon – the tenon which occurs on top of a post.

- Feather Tenon – a round-shouldered machined fillet or feather which is glued into a machine-made (router) slot or mortise on each side of the joint.

“Having an encyclopedic knowledge of how these homes go together is not necessary to enjoy their architectural elegance, or how they provide a strong connection to Mother Nature,” says Craig Johnson, vice president of sales and marketing at Woodhouse: The Timber Frame Company (Mansfield, PA). “But most homeowners take great pride in their timber frame homes, realizing the technology was passed down over thousands of years, by the tradesman that crafted them to stand the test of time.”

Johnson urges timber frame enthusiasts to reach out to Woodhouse’s regional project managers if they have any questions on any of the following terminology. These pros have been helping people realize the dream of timber frame living for decades, and they can provide valuable advice on each step in the design and building process.

See Related:

The Timber Frame Wood Species Woodhouse Employs

Dive Deeper: Woodhouse’s Glossary of Timber Framing Terms

Timber Home Living: Terminology

Getting Started

Choosing to build your forever timber frame home is an exciting journey few get to experience. You can be one of the lucky ones, by contacting Woodhouse’s regional project managers, or by using our contact form.